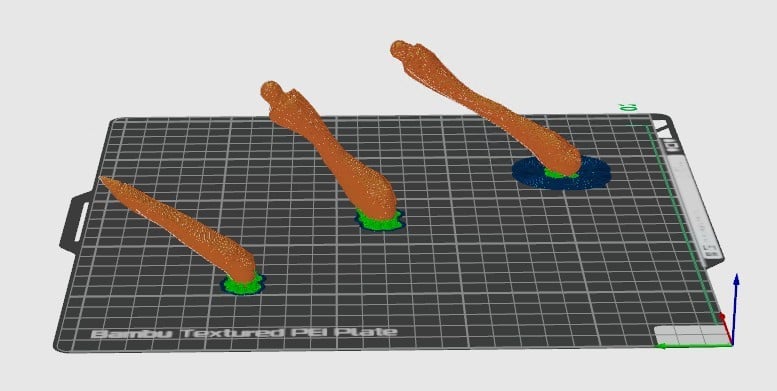

@Silvrav found the below enhanced print-in-place version of the tail, and a remixed body to take the new tail. I think I'm going to give this a try:

https://makerworld.com/en/models/1529323-facehugger-tail-realistic-version

https://makerworld.com/en/models/1529308-facehugger-body-remix

Legs I just grab them from the original model.