We are wanting to convert an existing built-in bookshelf to a back-light shelved unit for displaying glass art etc., ideally in the same manner that galleries use, eg:

The key aspect of such lighting is that the light comes from behind the art, therefore illuminates it in a particular way. (Any lighting that comes from in front of the art will fail for this reason.)

My initial thoughts (to keep the complexity/price down) had been to install LED strip-lighting on the backs of the shelving (which would be not quite touching the back of bookcase), however I'm thinking that will produce shadows and produce quite a different illumination (relying on reflection off the back of the space, which would be painted white). One alternative discussed was to rebate the shelves a bit at the back and run the strip lighting along that, so that the bulbs sit basically flush with the bottom of shelves, however this increases the likelihood of the lights being visible from when viewed from below the height of the shelf, and doesn't solve the problem the light will still be bouncing off the back wall to reflect through the glass.

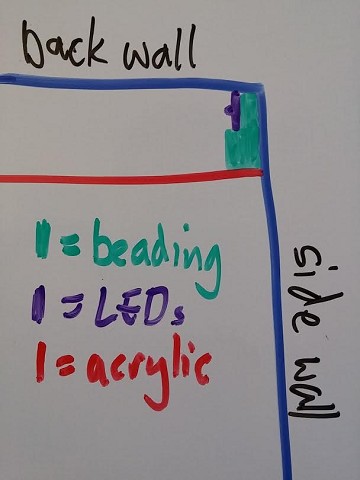

So, my latest thoughts are to try to replicate using a variation of the way galleries light such shelving, which is using flurorescent tube lighting behind white opaque glass/perspex. My plan is to use LED strip lighting (cheaper/wastes less depth); put in some beading around say 2cm deep x 1cm wide all the way around the back edges of the bookshelf - the strip lighting would then be stuck to the beading, while a sheet of something opaque would be attached to the other exposed side of the beading. As the space is fairly large (at a guess 80 x 210 cm), I'm also thinking of running beading along parallel where the shelving will go - this will allow both a further fixing point for the opaque backing and also another place where LEDs could be run to even out the lighting if needed.

Anyway, I'd appreciate any thoughts as to how this lighting project could be better executed.

I also have no good leads as to what I could use and where I could get something affordable for the back opaque sheeting - I imagine that perspex is fairly expensive? The material needs to be fairly solid as it would need to be sit very flat when attached in the vertical; it would also need to have a uniform level of opaqueness, given the lighing will expose any variation (so painting it myself wouldn't be an option!). It would also need to have some degree of scratch resisitance. Could I get some decently thick plastic sheeting and then have a firm apply a white film to one side of this?

Thanks for any thoughts and ideas!

#

#