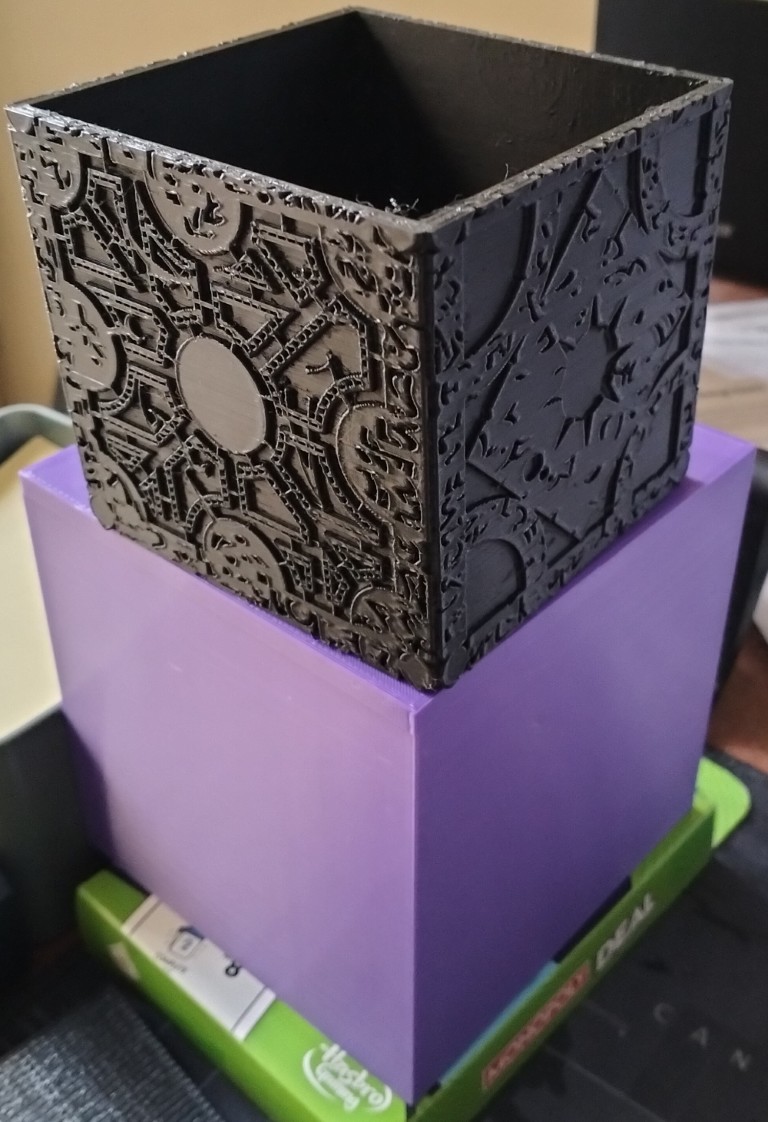

I finished printing the last parts for a box last night, the top and the base. The base is fine, the 4 sides are fine but the lid is all sorts of screwed up. Taking it off the build plate its like it delaminated into three bits. Most unusual. I have printed the top previously without any issues on a previous roll of PLA - both rolls are creality branded, the current one first opened Saturday.

I'll try redoing it later when I get home. Or just not bother! I did change the infill / pattern from default but I wouldnt have thought that would make a big difference, at least it never has in the past.

The printer in question is a Ender3 V2. I print at 210 with a bed of 60. I have found that works well for that particular PLA after lots of trial and error.

The actual print looks correct on the top and the bottom. Maybe the STL was a little iffy. Not sure if I used that one the first time or another. The plan next is to print the whole box as one piece rather than 5 and the top separate. Just dont want to get to the end of a 24 hour print for it to fail!

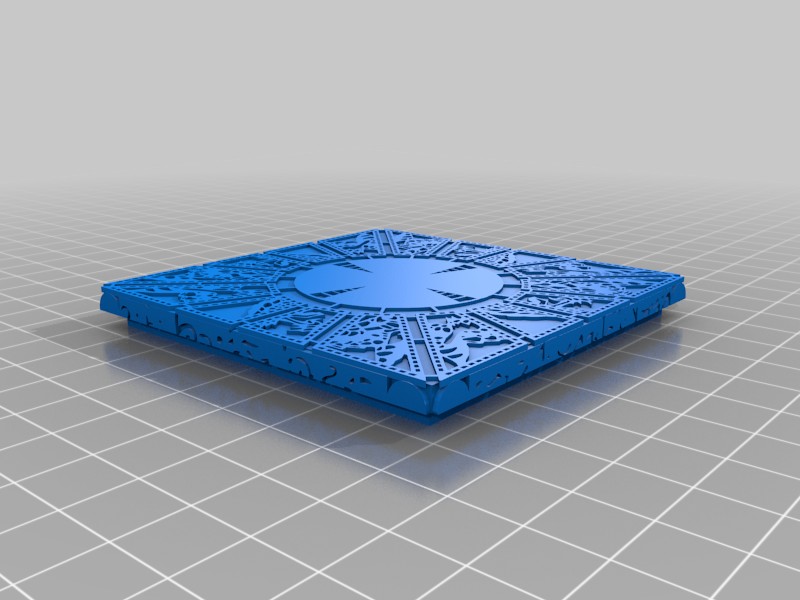

What it should look like: