|

|

|

mailmarshall: Have found that the thicker gauge feels bit more quieter when it rains heavily - not sure if this is scientific or just a feeling.

RickW: ...

I need to do my roof and I'm going to go for 0.55 gage endura because I know that I will get close to 50 years out of it if cared for correctly. Also if you can afford it I highly recommend Cover tech 407 or equivalent paper instead of the bitumen based paper as it will not deteriorate and will last as long as the roof and will lead to a lot less leaks in the years ahead.

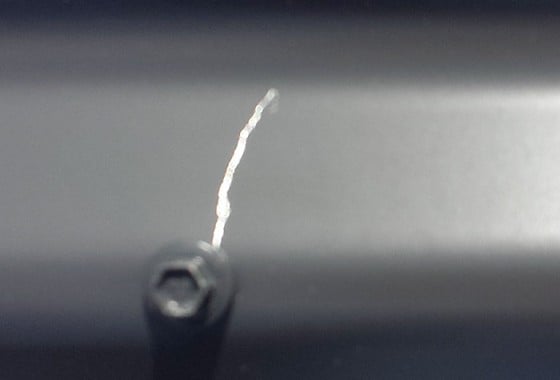

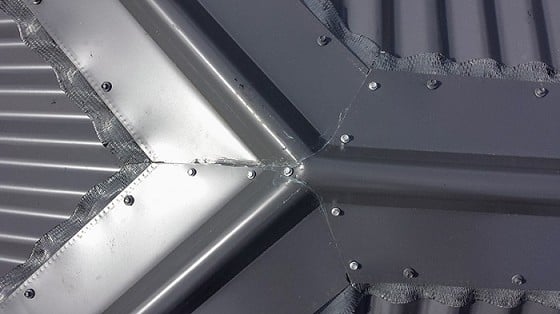

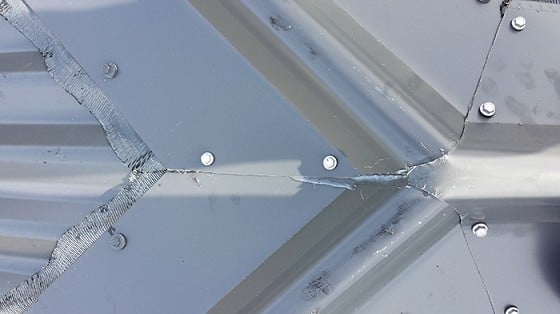

The main things to look for is there are no scratches on the sheets after they have been installed as they will rust out quickly, even if touch up (paint) is used. Not to mention touch up will discolour a lot more quickly than the iron. Even little dents will eventually become holes/splits. Imagine bending metal back and forth until it breaks this is what happens in the sun when the sheets expand and contract and a dent is the weakest point so will bend. Scratched or dented sheets really need to be replaced. Make sure the sheets are cut with gilbows or reds or greens and not a grinder. And check that the washers on the screws are roughly 2/3 compressed and none split and coming out the side of the screw head. And a absolute must is the roof and gutter MUST be blown off every day to ensure no swarf is left on the iron and better yet hose the roof off after the roofers have left each day. Insure the top of the sheets awe "turned up" which is the low/pan of the sheet being folded up at a 90 degree angle to the sheet to insure that water that will get under the hips/ridges in wind/rain cannot get over and therefor under the sheets.

Hammerer:mailmarshall: Have found that the thicker gauge feels bit more quieter when it rains heavily - not sure if this is scientific or just a feeling.RickW: ...

I need to do my roof and I'm going to go for 0.55 gage endura because I know that I will get close to 50 years out of it if cared for correctly. Also if you can afford it I highly recommend Cover tech 407 or equivalent paper instead of the bitumen based paper as it will not deteriorate and will last as long as the roof and will lead to a lot less leaks in the years ahead.

The main things to look for is there are no scratches on the sheets after they have been installed as they will rust out quickly, even if touch up (paint) is used. Not to mention touch up will discolour a lot more quickly than the iron. Even little dents will eventually become holes/splits. Imagine bending metal back and forth until it breaks this is what happens in the sun when the sheets expand and contract and a dent is the weakest point so will bend. Scratched or dented sheets really need to be replaced. Make sure the sheets are cut with gilbows or reds or greens and not a grinder. And check that the washers on the screws are roughly 2/3 compressed and none split and coming out the side of the screw head. And a absolute must is the roof and gutter MUST be blown off every day to ensure no swarf is left on the iron and better yet hose the roof off after the roofers have left each day. Insure the top of the sheets awe "turned up" which is the low/pan of the sheet being folded up at a 90 degree angle to the sheet to insure that water that will get under the hips/ridges in wind/rain cannot get over and therefor under the sheets.

We have regretted not having advice as good as this . The cumulative difference is easily visible 20 years on even after repainting. But not cleaning up after our builders was not as bad as forgoing the thicker gauge:

- thicker is noticeably quieter when it rains and when someone walks around on on it

- thicker doesn't dent as easily

- thicker extends the life of the roof by many years

On that last point, I've observed that a well maintained roof generally lasts until it corrodes from below. I've been helping friends and family extend the life of their roofs by replacing fixings etc and all of them are corroding from underneath not from above. The worst are where a bathroom has been vented into the ceiling cavity or the ventilation duct has leaked. The benefit of buying a thicker gauge, e.g. from .40mm to .55mm, is more than an additional 38% thickness. If the roof starts failing at an average of say .20 then the extra .15 thickness effectively means a 75% improvement which is twice the benefit and that translates to a lot of extra durability and life.

PS We also decided we should have gone for corrugated because of the additional strength it provides. Our fancy profile looks good but dents too easily and is more difficult to repaint.

|

|

|