Can I crimp a bootlace onto a fine wire and then crimp an automotive terminal onto the bootlace?

Background

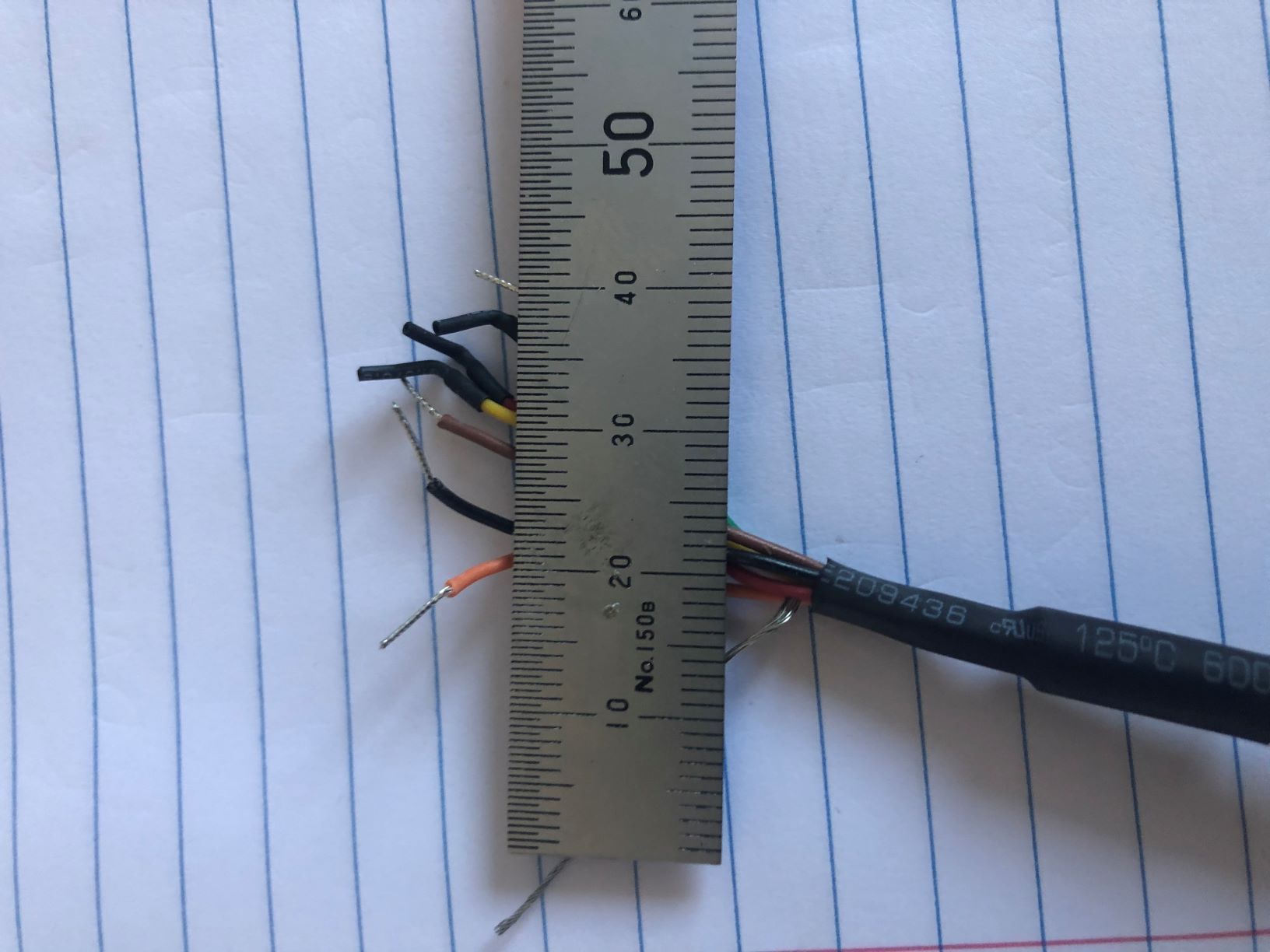

I have some very, fine (>AWG-24) wires (NMEA-0183 leads) that I need to terminate on my boat. This lead carries the position data from the plotter to the VHF

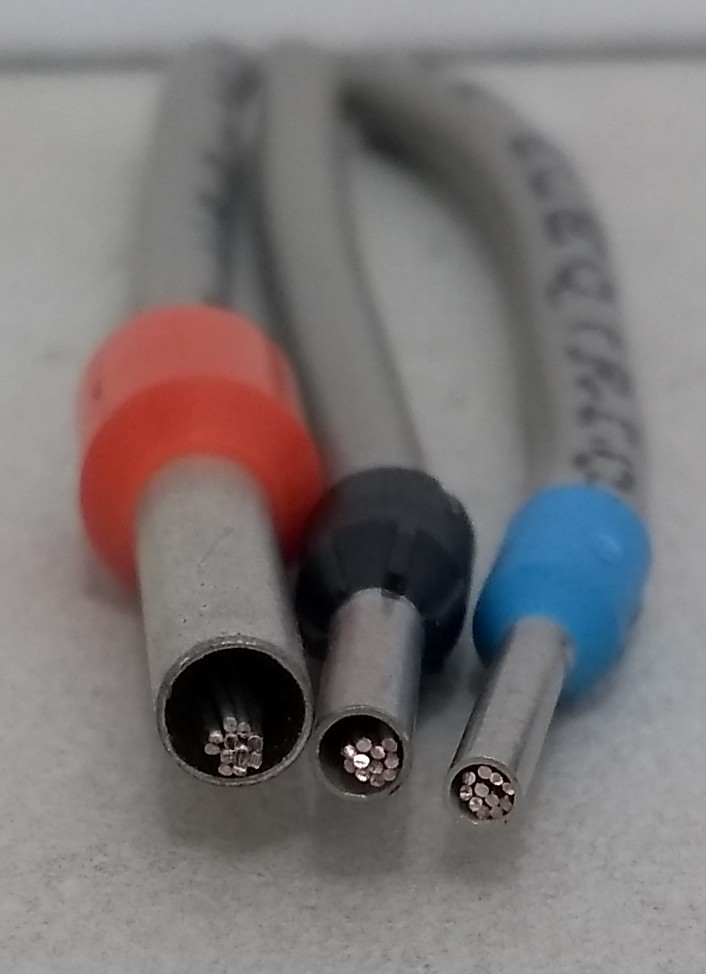

As this is a marine application, I'm using adhesive heat shrink terminals , overlaid with adhesive heat shrink tube, onto a ring-screw terminal block.

The terminals I'm using, don't crimp down tight enough for the very fine wires the manufacturer provides (please note the spec for the terminals seems to be in wire diameter, not mm2).