I've spent a bit of time the last few months trying assorted face mask powerups. These are my pick so far:

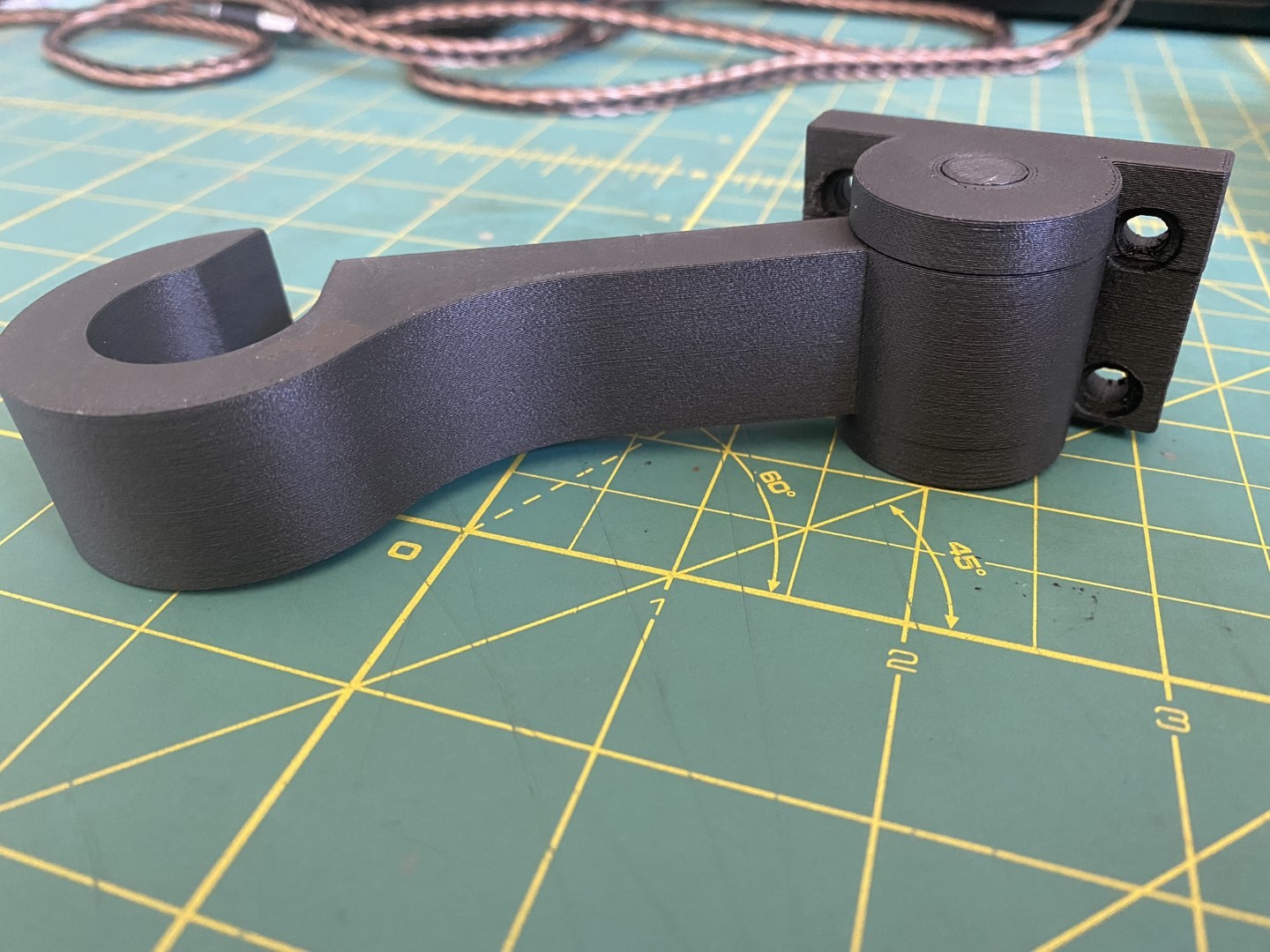

Ear saver: https://www.thingiverse.com/thing:4267885. Two part design that is adjustable. I've had a couple break, but very quick to print.

Nose clip / anti classes fog: https://www.thingiverse.com/thing:4635429. Not as good as a mask with a decent metal nose bridge, but great for the disposable masks that don't have anything/a paperclip bit of wire.