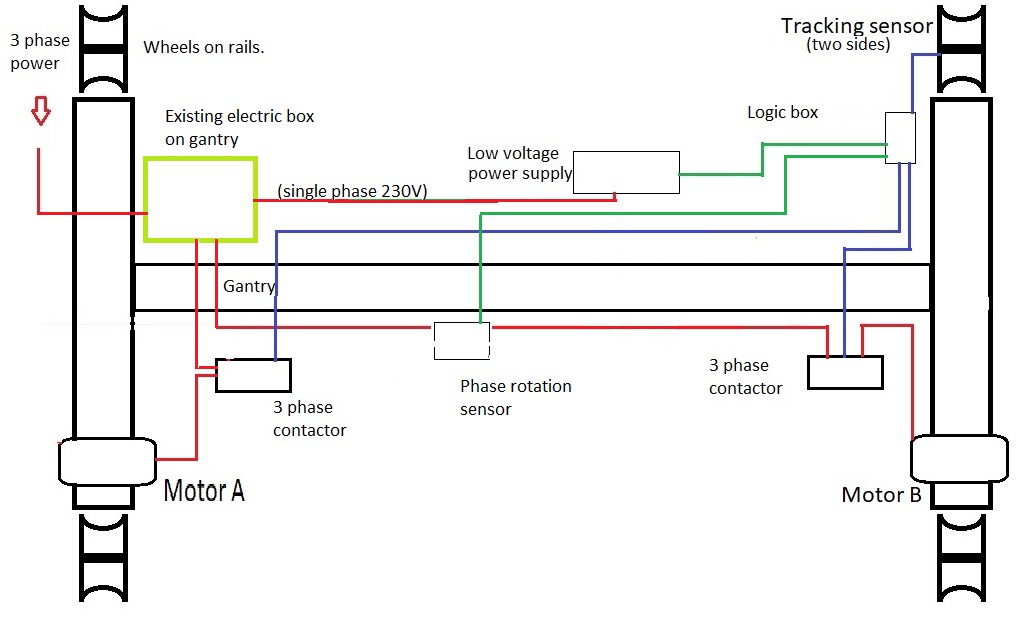

Yeabut, will they tell me phase rotation direction before switching motor on? When I start this machine I want to know which way it is going to go and the supply comes from a remote control panel which has reversing capability and I have no way of telling if they have selected forward or reverse.

Resistance voltage dropping was not my first choice and I was assuming there must be something better.

Yes. You wire the relay input to the supply (potentially via fuses). It doesn't care whether you have loads connected or not; it just moves a contact to tell you what the status is, and your controls can decide to start up a motor or select a direction based on that.

Capacitive droppers can be an option but introduce a phase shift (this shouldn't matter as the shift on all three phases should be identical), and still need some series resistance to provide inrush limiting.

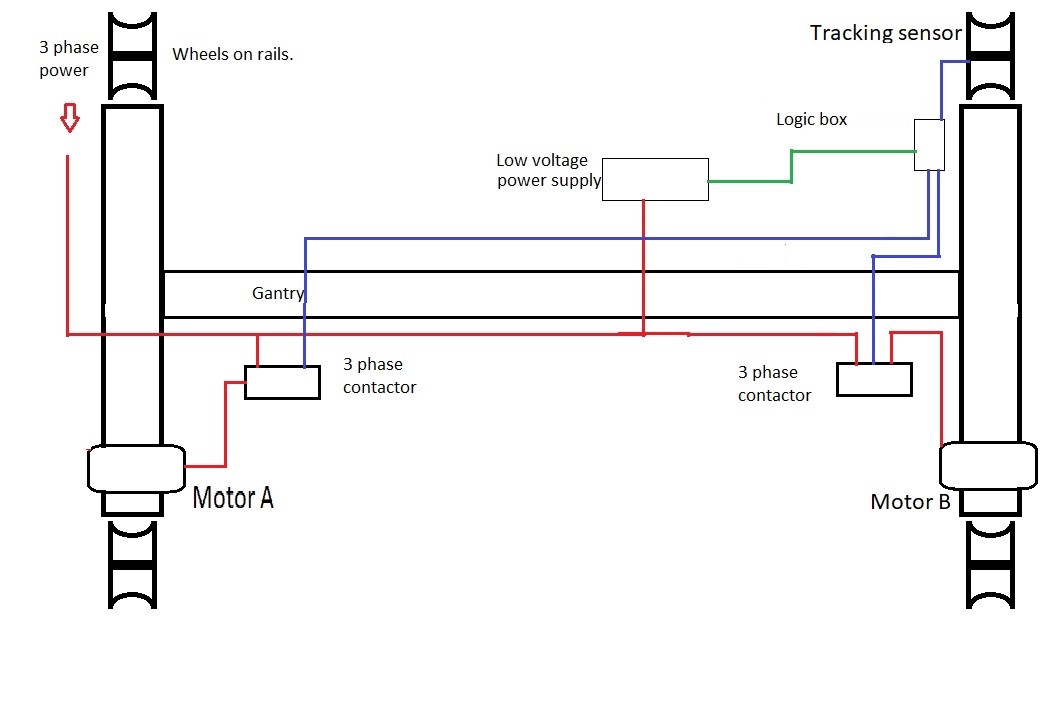

The scheme being considered starts and stops the 750w motors via solid state contactors which advertise soft starting. I have no doubt that the multitude of pumps, vacuum pumps, compressors and irrigators in the immediate vicinity will be kicking up a fair racket electrically but I expect there will be scope for filtering the trickle of 400V being bled off to the optocouplers.

Have you priced out the cost difference between VFDs and soft starters? For small motors like this, something like a WEG CFW300 or ABB ACS55 can be pretty cost-effective.