|

|

|

Note that's 1.4/1.6 kilowatt-hours per day, not straight kilowatts.

I.e. an average of 58 or 67 watts.

Hence why HWC cupboards make a nice airing/linen cupboard space, but aren't super hot like if you had a fan heater in there 24/7.

Ah, yeah, forgot the 'h'. Also the graph claims the storage temperature is 55K so it's apparently some sort of cryogenic storage rather than a HWC.

It's looking more and more like it'll be a Rheem 180L if I can't get a reply from Rinnai, they've got thermal sensor pockets at least, and the slight extra heat loss isn't a biggie, particularly since I'll be wrapping it to the max.

You're reading just the graph axes, not the surrounding text:

For New Zealand and Australia, electric water heaters are tested for their standard heat loss at a

nominal 20°C ambient air temperature and a water storage temperature of 75°C (for most tanks), giving

a ambient air/hot water temperature difference of 55°C .

[...]

Figure 6. Maximum allowable heat loss rate (kWh/day at 55°C temperature difference) for electric storage water heaters

plotted against volume (in litres)

So it's talking about a 55K differential, which is perfectly accurate unit usage - and probably somewhat higher than expected in reality, as the cylinder is probably set at 60-65. Ambient temperature will depend on location. In a linen closet, it's probably >15C year round and often much warmer.

Handle9:

johno1234:

How about an outdoor sited monoblock heat pump HWC? They work well with solar and you get an indoor cupboard back.

If you switch to mains pressure you may need to replace pipes and mixers throughout the house.

You need to use a lot of water for them to make any economic sense. The life is almost guaranteed to be a fraction of the life of a resistive cylinder as you are replacing an element and a tank with a compressor and refrigerant. They make sense in some situations but the economics don’t stack up today for most.

A heat pump HWC install will cheer up a morose polar bear adrift on an ever shrinking iceberg.

Don't discount that.

Finally got a reply from Rinnai, just after 5pm:

You can get a 135L cylinder with 2kW element. The element has two dry probe pockets which can be used when installing with Solar connections.

So they're perfectly usable with solar, they just don't tell you anywhere either on the web page or their technical docs. It'll just be a case of sliding an 18B20 into one of the probe pockets, I assume the thermostat uses one pocket and the 18B20 can go in the other.

neb:

The advantage of staying with the 135L is that it'll just slide in to replace our existing one,

double check the sizing's. very few are sized to the old sizing's. my new one is taller which means i lost my airing cupboard above it. most others where to wide

Dimensions are identical to the existing one. Must have already been MEPS-compliant in the early 1980s, which would also explain why it holds the heat so well.

A followup question, have HWC wraps gone out of fashion? When we did the 1984 one you just went down to Bunnings or M10 and bought some, now the only one that seems to exist is the Greenstuf which is out of stock almost everywhere that would in theory carry it. I know that MEPS cylinders have better insulation but there's still a ton of old cylinders around that don't have any decent insulation, but it seems like there's no longer any way to retrofit them.

neb:

A followup question, have HWC wraps gone out of fashion? When we did the 1984 one you just went down to Bunnings or M10 and bought some, now the only one that seems to exist is the Greenstuf which is out of stock almost everywhere that would in theory carry it. I know that MEPS cylinders have better insulation but there's still a ton of old cylinders around that don't have any decent insulation, but it seems like there's no longer any way to retrofit them.

As far as I am aware you can no longer get them. I have previously tried about a year ago to get around 5 for a project I was involved in and was unable to source any at all.

That's really annoying, when we installed ours there was a big push to get old cylinders wrapped, and now it's pretty much impossible even though the same old cylinders are still around. If I'd known I'd have been more careful cutting the wrap around the scrapped one away.

Really nicely done, catch tray at the bottom with 40mm drain to the outside, the white object by the drain is a water leak sensor, everything is accessible next to the HWC rather than via a service hatch underneath, and it's mains pressure SS so it should last a long time. Under the drip tray is a sheet of 12mm ply to go over the top of the weetbix flooring, and the weetbix has been sealed with some leftover urethane varnish in case any moisture gets out. Just waiting for the electrician so I can finish wrapping and strapping everything.

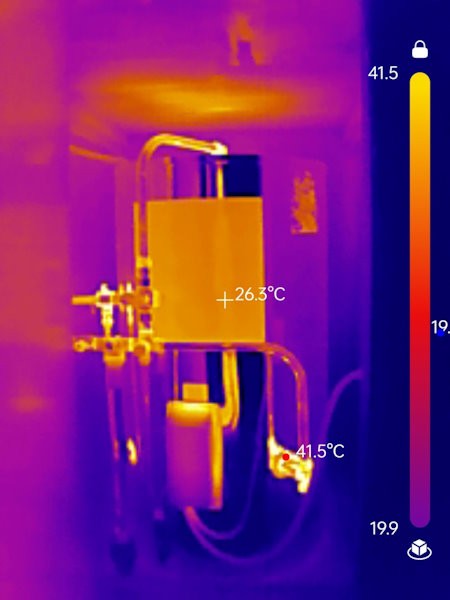

Here's the thermal performance for the new HWC:

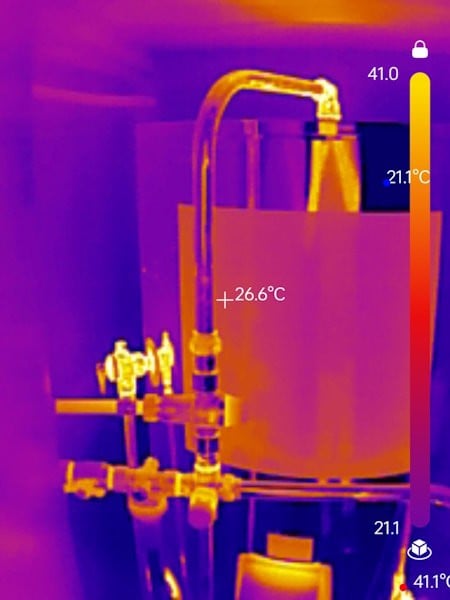

Gosh, who would have thought that running copper heat pipes outside the thermal envelope would lead to it bleeding heat like crazy?

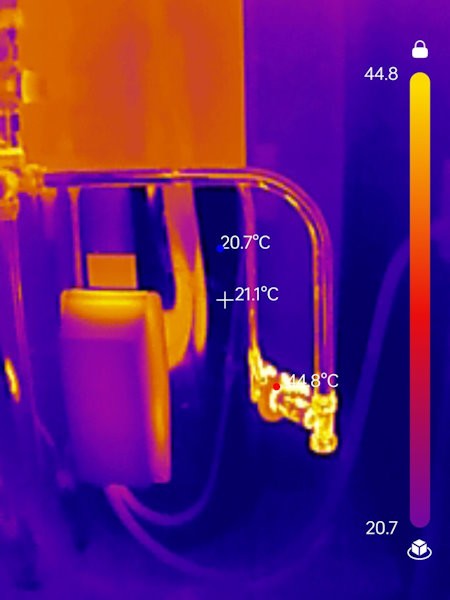

This is the hot water piping, however even the cold water inlet leaks heat:

Finally, the metal jacket is also a source of heat loss, the large square at 26 degrees is the paper sticker on the front of the cylinder which is stopping the heat under it from being radiated away like the rest of the metal body.

I've also noticed it in terms of heating, the 1984 thermally-wrapped cylinder reheated maybe once a day, this one is already on its third reheat today.

I'm pretty sure lagging pipes within the first ~2m of the cylinder is a building code requirement for obvious reasons.

Modern thermostats might have a tighter temperature differential; I wouldn't use that as a measure of how much heat loss there is.

I'm not sure I see a proper TPR valve? I thought they needed to be as close to the top of the cylinder as possible, ideally with the probe in the cylinder.

The TPR valve is the very hot thing that's topmost on the left of the cylinder in the second photo.

Going back to a previous post, you can still get cylinder wrap from Elite Insulation in Otahuhu, Auckland, who will also ship around the country. It's not cheap, but probably worth it particularly if you're on solar.

SomeoneSomewhere:

I'm not sure I see a proper TPR valve? I thought they needed to be as close to the top of the cylinder as possible, ideally with the probe in the cylinder.

i wondered about that but a lot of rinnai tanks are setup like that with tpr on the side as they only have a single top outlet. personally i prefer it on top as its easier to bleed the air out of it.

|

|

|