I have a project in mind that I think would be well suited to aluminium t-slot extrusion. I've never used the t-slot stuff before and am not even sure what terms I should be googling to learn more. Everything I have tried so far seems to pop up with office furniture related links.

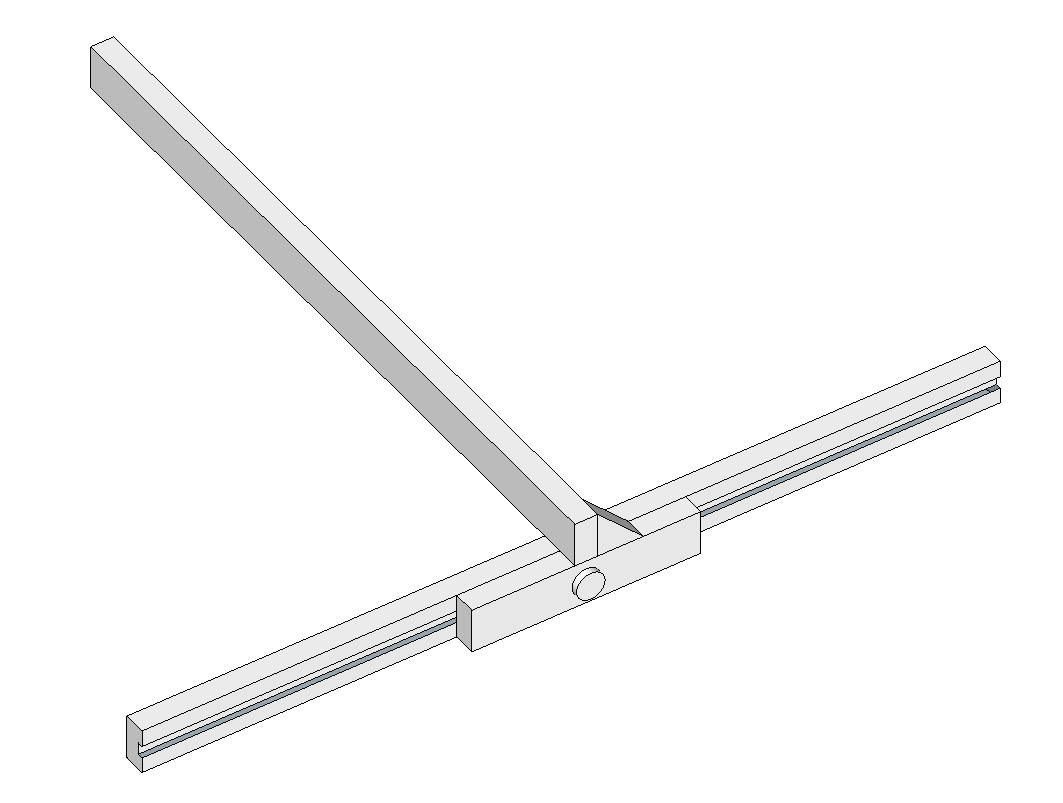

What I want to build is basically a t-square, but with the ability for the blade (the long bit) to be loosened and moved along the stock (the short bit) and re-tightened. Once re-tightened, it should be back to a true square/90 degrees. I want to see if I can figure out a better approach to a table saw fence. My current wooden one is okay, but there is definite play in it an a couple of bits are just slightly off true.

I think I've figured out that 4020 t-slot should work well, but I'm still trying to work out the range of various fasteners and things.

Any guidance on what I should be looking for (or the terms I should be googling would be appreciated).

Also, any local suppliers and hints on how to work with it wouldn't go astray - is an aluminium cutting blade on a drop saw or table saw sufficient? Or should I be using a grinder and abrasive cut off discs?