In terms of a convenient base to put the whetstones in, a plastic planter tray from anywhere that sells gardening supplies is perfect, once you're done you just rinse it out, with no mess left in the work area.

In terms of a convenient base to put the whetstones in, a plastic planter tray from anywhere that sells gardening supplies is perfect, once you're done you just rinse it out, with no mess left in the work area.

|

|

|

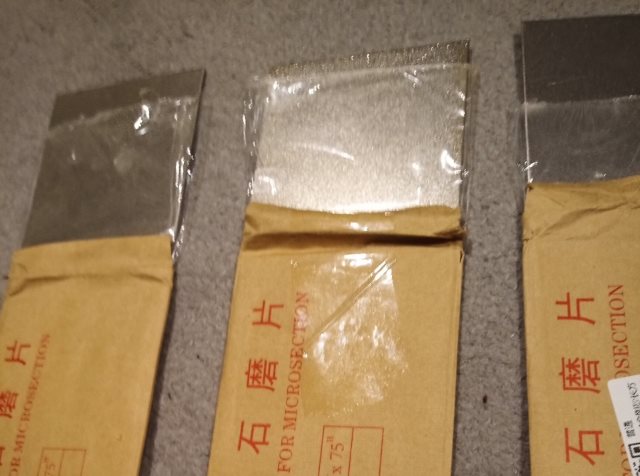

The 400 and 1000 feel about right, the 3000 is too fine to tell what it actually is. They're on pretty solid blocks of metal, maybe 1.5mm, I was initially going to glue them side by side to something like a PVC slab but that's going to be bigger than the water tray they'll be sitting in so perhaps just something non-slip for each block so it doesn't slide around in the tray, and to keep water off the back side.

Another thing with the electroless nickel plating process used for these is that you start with several layers of diamonds stacked on top of each other that abrade away to reveal the base abrasive surface, so it'll take a few uses before I can report back results. I'm also not going to use it on the plane blades for now because initially they're quite aggressive until they wear back to the base layer, I have some older chisels that'll be the guinea pigs.

I want to make myself a chisel bevel guide. I think I have enough skill to make a basic one.

An example of a professional one:

DarthKermit:I want to make myself a chisel bevel guide. I think I have enough skill to make a basic one.

In theory all you need is a machinists angle block, so you start with the tool resting against the block to set the correct angle and slide it up and down the waterstone, as long as you don't change the angle as you move the blade that may be enough. You can get the blocks relatively cheap from China, or cut one out of thick plastic if you've got the appropriate cutting tool.

using a flattening stone which is just a granite slab with a series of grooves cut in it with a diamond saw to carry the slurry away. Results are pretty impressive:

The surface is dead flat and probably close to as-new condition:

Now I can finish honing the plane blades...

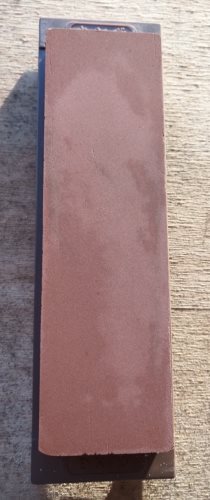

neb: I've just finished restoring the badly-cupped inherited whetstone of Japanese but otherwise unclear origin:

Oh gawd, just realised, it's a Global King, mass-produced resin-bonded aluminium oxide.

Well, at least it was a learning exercise.

I'm in the market for some better sharpening methods. I end up just bodging the job and have had to put new edges on a few knives/chisels recently that took far longer than it should have.

I have a copy of this at home that I surprisingly frequently flick through too. It's a bit of a pity that drill bits are so cheap that they become a disposable commodity once blunt. Sharpening them isn't all that hard.

Has anyone tried anything like the Lansky sharpening rod system? I'd be interested to hear a lay-persons thoughts.

Disrespective:Has anyone tried anything like the Lansky sharpening rod system? I'd be interested to hear a lay-persons thoughts.

I haven't tried that specifically, but I'm always a bit sceptical about gadget-style sharpeners, leading to extremes like those eyewateringly-expensive spring-loaded Rube Goldberg devices that try and mimic just doing it right yourself. If you just want to re-sharpen a knife and don't care about the details, get one of those drag-the-blade-through tungsten-carbide grinders, a.k.a. pull-through sharpeners (ugh) and use that while I look away... no, while I'm in another room... in a different house... possibly crying. OTOH if you're serious about a fine edge then I don't know how much a gimmick-style sharpener will help, you really just need to set the angle and then hone it. Firstly, steel it regularly, which just requires a bit of practice to set the angle right, I don't know if there are gadgets for that. If you don't trust your eye you can get silicone wedges that you hold at the top of the steel, line the knife up, and then stroke it down. Then for actual sharpening... well, I like my Chinese foam blocks, you can touch up a knife in thirty seconds without having to bother with whetstones and fluid and the mess it makes.

Having said that, just as there are a million types of sharpeners, there are also a million different opinions on which one is best, and a lot of it is down to religion. For example I think it's pointless to hone a plane blade with a 12,000 grit oilstone when you're going to lose the edge after the first 5cm of wood you put it through, but some people still insist on doing it. I'm also pretty sure there are people out there who would crucify me for liking the Chinese foam method.

It also depends on the quality of the blade, doing a super sharpening job on low-grade highish-carbon steel or some Warehouse-bought allegedly-stainless steel knife is probably a waste of time...

Disrespective:

Has anyone tried anything like the Lansky sharpening rod system? I'd be interested to hear a lay-persons thoughts.

I was given one recently and I have only tried it on my bluntest fishing knife, so far I am not convinced but I see there are stands and clamps for them. Someone said to me to put in in the vice, I will try that this weekend.

I really want one of these.

I cant justify the money however.

If I had a better workshop I would make one.

John

I know enough to be dangerous

Disrespective:I'm in the market for some better sharpening methods. I end up just bodging the job and have had to put new edges on a few knives/chisels recently that took far longer than it should have.

I have a copy of this at home that I surprisingly frequently flick through too. It's a bit of a pity that drill bits are so cheap that they become a disposable commodity once blunt. Sharpening them isn't all that hard.

Has anyone tried anything like the Lansky sharpening rod system? I'd be interested to hear a lay-persons thoughts.

Sometimes I just sit and think. Other times I just sit.

SATTV:I really want one of these.

I cant justify the money however.

There are endless copies of that style of sharpener on eBay and Aliexpress. Nowhere near the construction quality of the ScarySharp one, but that one does seem just a wee bit overengineered, you could sharpen a two-handed sword in that thing.

Yes I was. The kit I had is the same one that @SATTV is now using.

My thoughts, I'm sure it is a great sharpening system but I just never quite got the results that I was expecting. I know it comes down to the user but in the end I decided I didn't want to invest any further time to improve my technique so it went into a cupboard for the better part of 10 years.

My current knife sharpener is this which I picked up from IKEA a few years ago.

Nothing fancy to look at but it works surprisingly well. My current knives would be called upper consumer grade so they haven't cost me a lot. If I had invested in better quality knives I wouldn't let them near this IKEA contraption, I'd probably take them to an expert to be honest.

Pretty sure I've posted this before, but I use the Paul Sellers technique. I'd like a bevel guide for chisels at some stage, but the big advantage of this approach (to me) is that it's fast and easy so I do it often.

Chisels:

Plane irons:

I use the diamond stones for knives and scissors as well. Near enough is good enough for these (frankly, near enough is good enough for chisels and planes too; I'm not that good a woodworker).

He also suggests using wet and dry sandpaper on plate glass if you don't have diamond stones. I've tried this too and it is cheap and easy, but I tore the sandpaper to shreds eventually and very happy with the cheap diamond ebay plates I ended up with.

|

|

|