Hello,

Just a question to Sparkies and the like on here.

I have a single phase inverter welder I just got, it has a thick American 220V cable on it with a plug I have never seen before. 12AWG cable, 3.31mm2 cores, about a meter long.

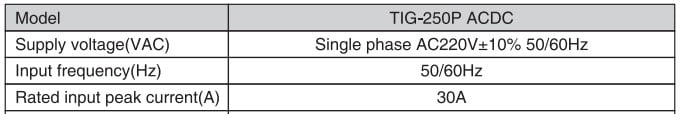

Anyway, the back of the unit states 21A Eff current, 40A Peak. However the manual states its 220V+/-10%, 30A rated current. So assume the latter.

Plugs here are 10A for standard domestic, or 15A with the larger earth.

Then there are the industrial ones that have all sorts, 10, 15, 20, 32A etc, in single phase.

I then found there are oven plugs, which are similar shape to the regular 10/15A plugs, but have larger phase and neutral pins, and a weird C shape earth.

Pics for an example as they were easily found online.

I am just reaching out to see if its OK to use this plug/socket combo on things other than Ovens. I assume it is fine.

Plan is to cut the end off the cable first shown, and put a NZ plug on it. Ideally I don't want to go to the large orange industrial plug and socket as I don't need IP66 ratings etc. This Oven socket would work well if its OK to use.

2nd question, what is the TPS cable size appropriate for a dedicated socket back to the switchboard, nothing else on it. Will standard 2.5mm TPS do the job, and handle the 32A socket OK, or do I need to jump up to 4.0mm? As said, its only going to be this one plug/socket on this line, nothing else. Its about 6m to the switchboard.

I will be getting a sparky to do the work, but I am just getting the info required before I get them involved, so I am not upsold. I would normally do this all myself and might still do a bunch of it, but ill get them to wire it into the switchboard and sign it off.

Fully understand about advise given, no liability etc, just after some info thats all.

Thanks