|

|

|

Zeon:

Coming back to the topic at hand, it seems to me that battery is not viable compared to a gaseous or liquid fuel for vehicles/machinery that have very high utilisation time. For example, during a harvest you have a narrow window to get the combine harvester across all the fields so could work day and night. With liquid fuels like petroleum there is practically no downtime as the tank can accept the fuels as quickly as you can get it in there.

This doesn't seem possible with a battery vehicle.

Or a bus that runs 17 hours straight per day.

Is Hydrogen not a valid fuel if you want to "decorbonise" and not use petroleum fuels?

It's not so much about the time running but the amount of power used. For a vehicle like a bus, 17 hours a day isn't necessarily a problem if they've got a few hundred km's of range and they're just driving in 50km/h speed zones. Lower speeds or even stop go traffic are beneficial to the range in an EV.

This applies to things like farm machinery too. They don't tend to be moving at high speeds so most of the power draw will depend on what accessories are attached. Recharging them isn't likely to take as long as you might think. There's no reason that can't happen within 20-30mins using current technology. However, we're still a ways off from electrifying farm machinery (battery or fuel cell) so in the years before that happens I imagine the recharge times will have improved even further.

Looking to buy a Tesla? Use my referral link and we both get credits

MikeAqua:

I think it depends on the business. We find it helpful to be able to get into a room in front of a white board/chart for problem solving. I've yet to find an online system that does this as well as in person.

It's difficult to do that stuff remotely but not impossible. I haven't been in the same country as my boss for the last 5 years so have some experience of it.

You do need to get together periodically, it makes a huge difference. It's also not suitable for a lot of jobs.

Swapping batteries is a possibility - this could even just be that you have a trailer behind the harvester and unplug & swap every so often. Or a direct mains solution.

The main issue with hydrogen is that its whole system efficiency is pretty poor. For every 1MWh generated electricity, you end up with somewhere around 750kWh at the motor with batteries, versus around 250kWh if you go through hydrogen first. That means you need to build far, far, far more power plants.

Or you generate the hydrogen by cracking natural gas, which defeats the whole idea of being largely carbon neutral.

https://c2e2.unepdtu.org/wp-content/uploads/sites/3/2019/09/analysis-of-hydrogen-fuel-cell-and-battery.pdf

Obraik:

It's not so much about the time running but the amount of power used. For a vehicle like a bus, 17 hours a day isn't necessarily a problem if they've got a few hundred km's of range and they're just driving in 50km/h speed zones. Lower speeds or even stop go traffic are beneficial to the range in an EV.

This applies to things like farm machinery too. They don't tend to be moving at high speeds so most of the power draw will depend on what accessories are attached. Recharging them isn't likely to take as long as you might think. There's no reason that can't happen within 20-30mins using current technology. However, we're still a ways off from electrifying farm machinery (battery or fuel cell) so in the years before that happens I imagine the recharge times will have improved even further.

In the other EV thread it came up with the interview with the head of JCB in the UK. They cannot electrify their vehicles which are mostly for construction, he made some good points, they have diggers that will double shift, and some running in India for something like 22 hours a day!

He says electric is absolutely perfect for consumer vehicles that only do a couple hundred hours of running a year. The issue they have is when they take a 20 tonne digger, and to electrify it, they have to add 8 tonnes of batteries, which makes it a 30 tonne digger, so they have to put the 30 tonne digger boom etc on it...

So they've been making ICE hydrogen to test. Run like petrol, but off hydrogen. He says it is up to the government to deal with the hydrogen storage. Fuel cells weren't economic.

https://www.youtube.com/watch?v=19Q7nAYjAJY

I'm looking forward to an electric future, but sadly for my driving I'm stuck with ICE until the range (and price improves).

mudguard:

In the other EV thread it came up with the interview with the head of JCB in the UK. They cannot electrify their vehicles which are mostly for construction, he made some good points, they have diggers that will double shift, and some running in India for something like 22 hours a day!

He says electric is absolutely perfect for consumer vehicles that only do a couple hundred hours of running a year. The issue they have is when they take a 20 tonne digger, and to electrify it, they have to add 8 tonnes of batteries, which makes it a 30 tonne digger, so they have to put the 30 tonne digger boom etc on it...

So they've been making ICE hydrogen to test. Run like petrol, but off hydrogen. He says it is up to the government to deal with the hydrogen storage. Fuel cells weren't economic.

https://www.youtube.com/watch?v=19Q7nAYjAJY

I'm looking forward to an electric future, but sadly for my driving I'm stuck with ICE until the range (and price improves).

Anything involving weight, rapid refuelling or that can be serviced from a centralised depot makes sense to move to hydrogen. But for light vehicles, EVs are fine. There's enough of a weight penalty from existing ICE that a battery and electric motors can eat into before a car become considerably heavier.

Trains, trucks and heavy industrial are prime for hydrogen. But retrofitting every filling station in the country to service light traffic as well will cost enormous amounts of money in today dollars that will have generate a return over time. Given the hugely escalating price of fuels in this country, I would prefer to not go down a road that locks in existing market structures and power bases for everyday driving.

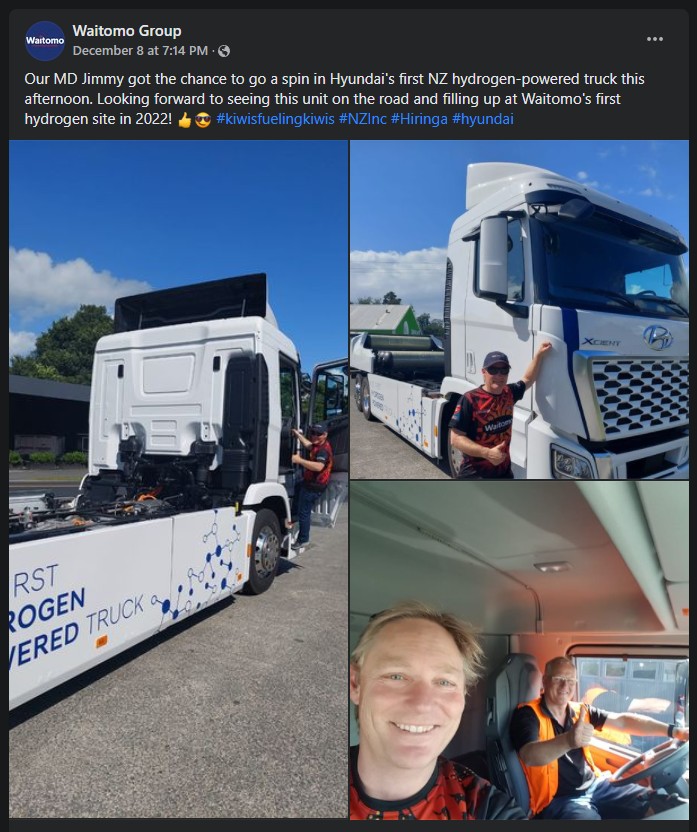

Waitomo Group are taking a punt on Hydrogen.

This link then has a link to the press release from January 2020

https://www.waitomogroup.co.nz/about/future-fuel-solutions/

And this from there Facebook page the other day.

Toyota / Lexus Hybrid and EV Battery Expert Battery Test & Repair

mudguard:

Obraik:

It's not so much about the time running but the amount of power used. For a vehicle like a bus, 17 hours a day isn't necessarily a problem if they've got a few hundred km's of range and they're just driving in 50km/h speed zones. Lower speeds or even stop go traffic are beneficial to the range in an EV.

This applies to things like farm machinery too. They don't tend to be moving at high speeds so most of the power draw will depend on what accessories are attached. Recharging them isn't likely to take as long as you might think. There's no reason that can't happen within 20-30mins using current technology. However, we're still a ways off from electrifying farm machinery (battery or fuel cell) so in the years before that happens I imagine the recharge times will have improved even further.

In the other EV thread it came up with the interview with the head of JCB in the UK. They cannot electrify their vehicles which are mostly for construction, he made some good points, they have diggers that will double shift, and some running in India for something like 22 hours a day!

He says electric is absolutely perfect for consumer vehicles that only do a couple hundred hours of running a year. The issue they have is when they take a 20 tonne digger, and to electrify it, they have to add 8 tonnes of batteries, which makes it a 30 tonne digger, so they have to put the 30 tonne digger boom etc on it...

So they've been making ICE hydrogen to test. Run like petrol, but off hydrogen. He says it is up to the government to deal with the hydrogen storage. Fuel cells weren't economic.

https://www.youtube.com/watch?v=19Q7nAYjAJY

I'm looking forward to an electric future, but sadly for my driving I'm stuck with ICE until the range (and price improves).

Excavators of that size already have ~5t of dumb steel counterweight, although you might need to do quite a bit of armouring given that it's right at the rear of the machine and tends to get quite beaten up...

I think excavators would probably do well with a hybrid system. It looks like Kobelco have had them available for a couple of years: https://kobelco-usa.com/media/ed22b48f-0d6a-492e-8210-ea07b6d6af94/Em3rzw/Brochures/Hybrid/KOBELCO%20SK210HLC-10%20NA.pdf?download=false

But especially for excavators doing delicate/stop-go work (trenching etc.) I think there could be far larger savings if they were able to stop the main engine and run just on an electric pump, and stop pumping fluid in circles when not necessary. There's a *lot* of idling hours, and pumping losses mean idle tends to be quite high.

Avoiding exhaust is also a priority in a lot of situations - an increasing number of forklifts, scissor lifts, & boom lifts are going full electric because you need mass anyway, and if they're being used indoors or in a tunnel/pit/trench the exhaust is a problem.

mudguard:

In the other EV thread it came up with the interview with the head of JCB in the UK. They cannot electrify their vehicles which are mostly for construction, he made some good points, they have diggers that will double shift, and some running in India for something like 22 hours a day!

He says electric is absolutely perfect for consumer vehicles that only do a couple hundred hours of running a year. The issue they have is when they take a 20 tonne digger, and to electrify it, they have to add 8 tonnes of batteries, which makes it a 30 tonne digger, so they have to put the 30 tonne digger boom etc on it...

So they've been making ICE hydrogen to test. Run like petrol, but off hydrogen. He says it is up to the government to deal with the hydrogen storage. Fuel cells weren't economic.

https://www.youtube.com/watch?v=19Q7nAYjAJY

I'm looking forward to an electric future, but sadly for my driving I'm stuck with ICE until the range (and price improves).

On the otherhand, Caterpillar unveiled a fully electric underground mining heavy machine, along with a mobile charger to go along with it that can recharge in 30mins or less than 20 if you have two. It looks like they're also coming up with some EV mining dump trucks

Looking to buy a Tesla? Use my referral link and we both get credits

Yup. The moment you go underground, you do *not* want to be dealing with fuel if at all possible. Exhaust and heat are not your friend.

MikeAqua:

I think it depends on the business. We find it helpful to be able to get into a room in front of a white board/chart for problem solving. I've yet to find an online system that does this as well as in person.

https://miro.com/ does a decent job, but you just can't beat in-person brainstorming.

rjh:

You aren't thinking outside the box. In Europe there is a trial of a stretch of motorway with overhead power. Trucks with pantographs can pick up power from this and recharge while moving.

Fine for trucks. But what about farm machinery or commercial boats or tractors or ...

Formula E is the ideal demonstration of the limitations of BEV. The drivers change cars during the race, because the batteries have gone flat.

Mike

SomeoneSomewhere:

Yup. The moment you go underground, you do *not* want to be dealing with fuel if at all possible. Exhaust and heat are not your friend.

The exhaust from hydrogen is water. What's the exhaust from a lithium battery fire?

Mike

Hydrogen vehicles also have lithium batteries. Not to mention the highly pressurised hydrogen tanks containing the most volatile substance...

Looking to buy a Tesla? Use my referral link and we both get credits

|

|

|